![]() Many Thermowells

are custom made, therefore, a complete "off the shelf" stock is

not possible. Items not in stock can usually be machined in about 7-10 days.

Many Thermowells

are custom made, therefore, a complete "off the shelf" stock is

not possible. Items not in stock can usually be machined in about 7-10 days.

Please consult our factory for availability, prices and quantity discounts.

Note: NPT or Nominal Pipe Thread (Tapered thread).

Note: NPSM or Nominal Pipe Thread Straight Mechanical (Thread straight, not tapered).

Note: .260 inch (6.60 mm) is the bore for 1/4 inch (6.35 mm) elements.

Note: .385 inch (9.78 mm) is the bore for 3/8 inch (9.53 mm) elements.

| Thermowell Style | Bore (Inches) | Bore (mm) |

Series # |

| Socket Weld Wells | .260 | 6.60 | T110 |

| Socket Weld Wells (Includes Sanitary Flanges) | .385 | 9.78 | T120 |

| Weld-in Wells | .260 | 6.60 | T150 |

| Weld-in Wells | .385 | 9.78 | T154 |

| Sub Socket Wells | T180 |

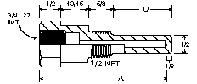

| SERIES T110 |

Socket

Weld Wells .260 bore ( 6.60 mm ) for 1/4 inch ( 6.35 mm ) element. |

| CODE | Material - MC | ||||||||||

| Construction | |||||||||||

| 06 08 07 09 10 11 16 18 20 22 47 A1 A2 BR CA CS HB HC N I MR MK TA TI |

Alloy 601 304 SS Type 446 SS Alloy 600 Alloy 800 F - 11 316 SS 309 SS 310 SS F - 22 347 SS A 105, Grade I A 105, Grade I I Brass Carpenter 20 Carbon Steel Hastalloy B Hastalloy C Nickel Monel R Monel K Tantalum Titanium |

|

|

||||||||

| Part Number Example:T11012-16-02 1/2 (#16 = 316 SS) |

Pipe Size P |

Element Length A |

Insertion Length U |

Shank Diameter Q |

|||||||

| inches | mm | inches | mm | inches | mm | inches | mm | ||||

| Use above chart to insert

material code Other materials available upon request |

T11012- MC- 02 1/2 T11012- MC- 04 1/2 T11012- MC- 07 1/2 T11012- MC- 10 1/2 T11012- MC- 13 1/2 T11012- MC- 16 1/2 T11012- MC- 22 1/2 |

||||||||||

| 3/4 Nominal (1.050 dia. actual) |

26.7 | 4 6 9 12 15 18 24 |

101.6 152.4 228.6 304.8 381.0 457.2 609.6 |

2 1/2 4 1/2 7 1/2 10 1/2 13 1/2 16 1/2 22 1/2 |

63.5 114.3 190.5 266.7 342.9 419.1 517.5 |

3/4 | 19.1 | ||||

| T11016- MC- 02 1/2 T11016- MC- 04 1/2 T11016- MC- 07 1/2 T11016- MC- 10 1/2 T11016- MC- 13 1/2 T11016- MC- 16 1/2 T11016- MC- 22 1/2 |

|||||||||||

| 1 Nominal (1.050 dia. actual) |

33.4 | 4 6 9 12 15 18 24 |

101.6 152.4 228.6 304.8 381.0 457.2 609.6 |

2 1/2 4 1/2 7 1/2 10 1/2 13 1/2 16 1/2 22 1/2 |

63.5 114.3 190.5 266.7 342.9 419.1 517.5 |

7/8 | 22.2 | ||||

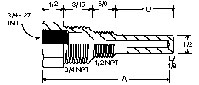

| SERIES T120 |

Socket

Weld Wells .385 bore ( 9.78 mm ) for 3/8 inch ( 9.53 mm ) element. |

| CODE | Material - MC | ||||||||

| Construction | |||||||||

| 06 08 07 09 10 11 16 18 20 22 47 A1 A2 BR CA CS HB HC N I MR MK TA TI |

Alloy 601 304 SS Type 446 SS Alloy 600 Alloy 800 F - 11 316 SS 309 SS 310 SS F - 22 347 SS A 105, Grade I A 105, Grade I I Brass Carpenter 20 Carbon Steel Hastalloy B Hastalloy C Nickel Monel R Monel K Tantalum Titanium |

|

|

||||||

| Part Number Example:T12012-16-02 1/2 (#16 = 316 SS) |

Pipe Size P |

Element Length A |

Insertion Length U |

||||||

| inches | mm | inches | mm | inches | mm | ||||

| Use above chart to insert

material code Other materials available upon request |

T12012- MC- 02 1/2 T12012- MC- 04 1/2 T12012- MC- 07 1/2 T12012- MC- 10 1/2 T12012- MC- 13 1/2 T12012- MC- 16 1/2 T12012- MC- 22 1/2 |

||||||||

| 3/4 Nominal (1.050 dia. actual) |

26.7 | 4 6 9 12 15 18 24 |

101.6 152.4 228.6 304.8 381.0 457.2 609.6 |

2 1/2 4 1/2 7 1/2 10 1/2 13 1/2 16 1/2 22 1/2 |

63.5 114.3 190.5 266.7 342.9 419.1 517.5 |

||||

| T12016- MC-

02 1/2 T12016- MC- 04 1/2 T12016- MC- 07 1/2 T12016- MC- 10 1/2 T12016- MC- 13 1/2 T12016- MC- 16 1/2 T12016- MC- 22 1/2 |

|||||||||

| 1 Nominal (1.315 dia. actual) |

33.4 | 4 6 9 12 15 18 24 |

101.6 152.4 228.6 304.8 381.0 457.2 609.6 |

2 1/2 4 1/2 7 1/2 10 1/2 13 1/2 16 1/2 22 1/2 |

63.5 114.3 190.5 266.7 342.9 419.1 517.5 |

||||

| Sanitary Flanges |  |

||||||||

| Add one of the following codes to the

end of the catalog number. SF00= Sanitary Flange SF16=1 inch SF24= 1 1/2 inch SF32=2 inch |

|||||||||

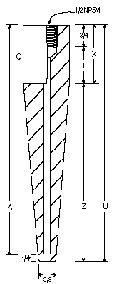

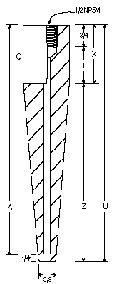

| SERIES T150 |

Weld-in

Wells, No External Thread .260 bore ( 6.60 mm ) for 1/4 inch ( 6.35 mm ) element. 1/2"NPT NPSM internal thread standard. Q = 1 1/2 shank diameter |

| CODE | Material - MC | ||||||||||

| Construction | |||||||||||

| 06 08 07 09 10 11 16 18 20 22 47 A1 A2 BR CA CS HB HC N I MR MK TA TI |

Alloy 601 304 SS Type 446 SS Alloy 600 Alloy 800 F - 11 316 SS 309 SS 310 SS F - 22 347 SS A 105, Grade I A 105, Grade I I Brass Carpenter 20 Carbon Steel Hastalloy B Hastalloy C Nickel Monel R Monel K Tantalum Titanium |

|

|

||||||||

| Part Number Example: T15000-16- 04 1/4 (#16 = 316 SS) |

Element Length A |

Insertion Length U |

Straight Length X |

Tapered Length Z |

|||||||

| inches | mm | inches | mm | inches | mm | inches | mm | ||||

| Use above chart to insert material code Other materials available upon request |

T15000-MC-04 1/4 T15000-MC-06 1/4 T15000-MC-09 1/4 T15000-MC-12 1/4 |

||||||

| 4 6 9 12 |

101.6 152.4 228.6 304.8 |

4 1/4 6 1/4 9 1/4 12 1/4 |

108.0 158.8 235.0 311.2 |

1 3/4 1 3/4 1 3/4 1 3/4 |

31.8 31.8 31.8 31.8 |

2 1/2 4 1/2 7 1/2 10 1/2 |

63.5 114.3 190.5 266.7 |

| T15000-MC-13 1/2 T15000-MC-16 1/2 T15000-MC-22 1/2 |

|||||||

| 15 18 24 |

381.0 457.2 609.6 |

13 1/2 16 1/2 22 1/2 |

342.9 419.1 571.5 |

8 3/4 11 3/4 17 3/4 |

222.3 298.5 450.9 |

6 1/2 6 1/2 6 1/2 |

165.1 165.1 165.1 |

| SERIES T154 |

Weld-in

Wells, No External Thread .385 bore ( 9.78 mm ) for 3/8 inch ( 9.53 mm ) element. 1/2"NPT NPSM internal thread standard. Q = 1 1/2 shank diameter |

| CODE | Material - MC | ||||||||||

| Construction | |||||||||||

| 06 08 07 09 10 11 16 18 20 22 47 A1 A2 BR CA CS HB HC N I MR MK TA TI |

Alloy 601 304 SS Type 446 SS Alloy 600 Alloy 800 F - 11 316 SS 309 SS 310 SS F - 22 347 SS A 105, Grade I A 105, Grade I I Brass Carpenter 20 Carbon Steel Hastalloy B Hastalloy C Nickel Monel R Monel K Tantalum Titanium |

|

|

||||||||

| Part Number Example: T15400-16- 04 1/4 (#16 = 316 SS) |

Element Length A |

Insertion Length U |

Straight Length X |

Tapered Length Z |

|||||||

| inches | mm | inches | mm | inches | mm | inches | mm | ||||

| Use above chart to insert material code Other materials available upon request |

T15400-MC-04 1/4 T15400-MC-06 1/4 T15400-MC-09 1/4 T15400-MC-12 1/4 |

||||||

| 4 6 9 12 |

101.6 152.4 228.6 304.8 |

4 1/4 6 1/4 9 1/4 12 1/4 |

108.0 158.8 235.0 311.2 |

1 3/4 1 3/4 1 3/4 1 3/4 |

31.8 31.8 31.8 31.8 |

2 1/2 4 1/2 7 1/2 10 1/2 |

63.5 114.3 190.5 266.7 |

| T15400-MC-13 1/2 T15400-MC-16 1/2 T15400-MC-22 1/2 |

|||||||

| 15 18 24 |

381.0 457.2 609.6 |

13 1/2 16 1/2 22 1/2 |

342.9 419.1 571.5 |

8 3/4 11 3/4 17 3/4 |

222.3 298.5 450.9 |

6 1/2 6 1/2 6 1/2 |

165.1 165.1 165.1 |

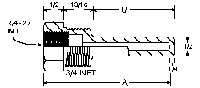

| SERIES T180 |

Sub Socket Wells |

| CODE | Material - MC | |||||

| Part Number | Class | Element Length A |

Insertion Length U |

Construction |

||

| inches | mm | inches | mm | |||

| 06 08 07 09 10 11 16 18 20 22 47 A1 A2 BR CA CS HB HC N I MR MK TA TI |

Alloy 601 304 SS Type 446 SS Alloy 600 Alloy 800 F - 11 316 SS 309 SS 310 SS F - 22 347 SS A 105, Grade I A 105, Grade I I Brass Carpenter 20 Carbon Steel Hastalloy B Hastalloy C Nickel Monel R Monel K Tantalum Titanium |

|||||

| T18001-MC-01 13/16 T18001-MC-02 13/16 T18001-MC-03 13/16 |

I | 3 4 5 |

76.2 101.6 127.0 |

|||

| 1 13/16 2 13/16 3 13/16 |

46.0 71.4 96.8 |

|

||||

| T18002-MC-01 3/16 T18002-MC-02 3/16 T18002-MC-03 3/16 |

I I | 3 4 5 |

76.2 101.6 127.0 |

1 3/16 2 3/16 3 3/16 |

30.2 55.6 81.0 |

|

| T18003-MC-01 3/16 T18003-MC-02 3/16 T18003-MC-03 3/16 |

I I I | 3 4 5 |

76.2 101.6 127.0 |

1 3/16 2 3/16 3 3/16 |

30.2 55.6 81.0 |

|

| Use above chart to insert material code Other materials available upon request |

T18004-MC-01 3/16 T18004-MC-02 3/16 T18004-MC-03 3/16 |

|||||

| I V | 3 4 5 |

76.2 101.6 127.0 |

2 3 4 |

50.8 76.2 101.6 |

For Class I V , Class I I above may be used |

|

| © Copyright 2005 Arklay S. Richards Co., Inc. |