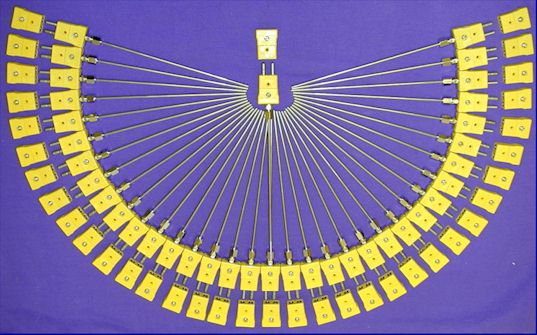

MgO type thermocouples have a compacted ceramic powder

insulation with

an outer metal sheath.

Temperature vs. Diameter and Material Table. Temperature limits are higher

than those of Miniature or Probe styles. Any flexing should be in an arc of

a reasonable radius - to tight an arc may cause failures in the thermocouple

element. Generally more expensive than Miniature of Probe styles. Jab-style

Jacks are standard.

Grounded junctions (G) are standard, but for Ungrounded (U) or Exposed Junctions

(E) change the "G" to "U" or "E" in the part

number.

For Dual elements insert "D" after "4" in part number. Example: 18K4DS9

| Type K Thermocouple Temperature Limits for Alloys | ||||||||

| Outside Diameter | Gauge (approx.) |

# 7 Alloy |

# 8 or # 16 Alloy |

# 9 or # 20 Alloy |

||||

| inch | mm | |||||||

| 3/4 (.7500) | 19.1 | 8 | 1090ºC | 2000ºF | 870ºC | 1600ºF | 1090ºC | 2000ºF |

| 1/2 (.5000) | 12.7 | 11 | 1090ºC | 2000ºF | 870ºC | 1600ºF | 1090ºC | 2000ºF |

| 3/8 (.3750) | 9.5 | 14 | 1090ºC | 2000ºF | 870ºC | 1600ºF | 1090ºC | 2000ºF |

| 5/16 (.3125) | 7.9 | 16 | 1090ºC | 2000ºF | 870ºC | 1600ºF | 1090ºC | 2000ºF |

| 1/4 (.2500) | 6.4 | 18 | 980ºC | 1800ºF | 870ºC | 1600ºF | 980ºC | 1800ºF |

| 3/16 (.1875) | 4.8 | 20 | 870ºC | 1600ºF | 870ºC | 1600ºF | 870ºC | 1600ºF |

| 1/8 (.1250) | 3.2 | 24 | 870ºC | 1600ºF | 870ºC | 1600ºF | 870ºC | 1600ºF |

| 1/16 (.0625) | 1.6 | 30 | 816ºC | 1500ºF | 816ºC | 1500ºF | ||

Consult factory for other available sheaths, and for Type N elements.

| Thermocouple

Types E, J, K, T - Plug only Thermocouples normally have the Plug on the thermocouple and the Jack on the Extension Wire, however, they may be made either way. Grounded junctions (G) are standard. |

||||||||

| Application | Tube Materials |

Wire Gauge |

Outside Diameter |

Type E | Type J | Type K | Type T | |

| Inch | mm | |||||||

| Sulfurous Atmospheres |

#7 Alloy (446) 23% Chromium Iron Type 446 Stainless |

14 |

3/8 (.3750) |

9.5 |

14J4S7-G-J4-* | 14K4S7-G-K4-* | |

|

| Used in food, beverage, chemical and other applications |

#8 Alloy (304) 10 % Nickel 19% Chromium Type 304 Stainless |

8 11 14 16 18 20 24 |

3/4 (.7500) 1/2 (.5000) 3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

19.1 12.7 9.5 7.9 6.4 4.8 3.2 |

18E4S8-G-E1-* 20E4S8-G-E1-* 24E4S8-G-E1-* |

18J4S8-G-J1-* 20J4S8-G-J1-* 24J4S8-G-J1-* |

8K4S8-G-K7-* 11K4S8-G-K4-* 14K4S8-G-K4-* 16K4S8-G-K1-* 18K4S8-G-K1-* 20K4S8-G-K1-* 24K4S8-G-K1-* |

18T4S8-G-T1-* 20T4S8-G-T1-* 24T4S8-G-T1-* |

| Used in most applications, good corrosion resistance |

#9 Alloy (600) 77 % Nickel 15% Chromium Stainless |

8 11 14 16 18 20 24 |

3/4 (.7500) 1/2 (.5000) 3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

19.1 12.7 9.5 7.9 6.4 4.8 3.2 |

18E4S9-G-E1-* 20E4S9-G-E1-* 24E4S9-G-E1-* |

18J4S9-G-J1-* 20J4S9-G-J1-* 24J4S9-G-J1-* |

8K4S9-G-K7-* 11K4S9-G-K4-* 14K4S9-G-K4-* 16K4S9-G-K1-* 18K4S9-G-K1-* 20K4S9-G-K1-* 24K4S9-G-K1-* |

18T4S9-G-T1-* 20T4S9-G-T1-* 24T4S9-G-T1-* |

| Food and chemical applications |

#16 Alloy (316) 12% Nickel 17% Chromium Type 316 Stainless |

11 14 16 18 20 24 |

1/2 (.5000) 3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

12.7 9.5 7.9 6.4 4.8 3.2 |

18E4S16-G-E1-* 20E4S16-G-E1-* 24E4S16-G-E1-* |

11J4S16-G-J4-* 14J4S16-G-J4-* 16J4S16-G-J1-* 18J4S16-G-J1-* 20J4S16-G-J1-* 24J4S16-G-J1-* |

11K4S16-G-K4-* 14K4S16-G-K4-* 16K4S16-G-K1-* 18K4S16-G-K1-* 20K4S16-G-K1-* 24K4S16-G-K1-* |

18T4S16-G-T1-* 20T4S16-G-T1-* 24T4S16-G-T1-* |

| Mechanical and corrosion resistance,

often used in chemical industries |

#20 Alloy (310) 20% Nickel 25% Chromium Type 310 Stainless |

14 16 18 20 24 |

3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

9.5 7.9 6.4 4.8 3.2 |

18E4S20-G-E1-* 20E4S20-G-E1-* 24E4S20-G-E1-* |

18J4S20-G-J1-* 20J4S20-G-J1-* 24J4S20-G-J1-* |

14K4S20-G-K4-* 16K4S20-G-K1-* 18K4S20-G-K1-* 20K4S20-G-K1-* 24K4S20-G-K1-* |

18T4S20-G-T1-* 20T4S20-G-T1-* 24T4S20-G-T1-* |

| Thermocouple

Types E, J, K, T - Jack only Thermocouples normally have the Plug on the thermocouple and the Jack on the Extension Wire, however, they may be made either way. Grounded junctions (G) are standard. |

||||||||

| Application | Tube Materials |

Wire Gauge |

Outside Diameter |

Type E | Type J | Type K | Type T | |

| Inch | mm | |||||||

| Sulfurous Atmospheres |

#7 Alloy (446) 23% Chromium Iron Type 446 Stainless |

14 |

3/8 (.3750) |

9.5 |

14J4S7-G-J5-* | 14K4S7-G-K5-* | |

|

| Used in food, beverage, chemical and other applications |

#8 Alloy (304) 10 % Nickel 19% Chromium Type 304 Stainless |

8 11 14 16 18 20 24 |

3/4 (.7500) 1/2 (.5000) 3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

19.1 12.7 9.5 7.9 6.4 4.8 3.2 |

18E4S8-G-E2-* 20E4S8-G-E2-* 24E4S8-G-E2-* |

18J4S8-G-J2-* 20J4S8-G-J2-* 24J4S8-G-J2-* |

8K4S8-G-K8-* 11K4S8-G-K5-* 14K4S8-G-K5-* 16K4S8-G-K2-* 18K4S8-G-K2-* 20K4S8-G-K2-* 24K4S8-G-K2-* |

18T4S8-G-T2-* 20T4S8-G-T2-* 24T4S8-G-T2-* |

| Used in most applications, good corrosion resistance |

#9 Alloy (600) 77 % Nickel 15% Chromium Stainless |

8 11 14 16 18 20 24 |

3/4 (.7500) 1/2 (.5000) 3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

19.1 12.7 9.5 7.9 6.4 4.8 3.2 |

18E4S9-G-E2-* 20E4S9-G-E2-* 24E4S9-G-E2-* |

18J4S9-G-J2-* 20J4S9-G-J2-* 24J4S9-G-J2-* |

8K4S9-G-K8-* 11K4S9-G-K5-* 14K4S9-G-K5-* 16K4S9-G-K2-* 18K4S9-G-K2-* 20K4S9-G-K2-* 24K4S9-G-K2-* |

18T4S9-G-T2-* 20T4S9-G-T2-* 24T4S9-G-T2-* |

| Food and chemical applications |

#16 Alloy (316) 12% Nickel 17% Chromium Type 316 Stainless |

11 14 16 18 20 24 |

1/2 (.5000) 3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

12.7 9.5 7.9 6.4 4.8 3.2 |

18E4S16-G-E2-* 20E4S16-G-E2-* 24E4S16-G-E2-* |

11J4S16-G-J5-* 14J4S16-G-J5-* 16J4S16-G-J2-* 18J4S16-G-J2-* 20J4S16-G-J2-* 24J4S16-G-J2-* |

11K4S16-G-K5-* 14K4S16-G-K5-* 16K4S16-G-K2-* 18K4S16-G-K2-* 20K4S16-G-K2-* 24K4S16-G-K2-* |

18T4S16-G-T2-* 20T4S16-G-T2-* 24T4S16-G-T2-* |

| Mechanical and corrosion resistance,

often used in chemical industries |

#20 Alloy (310) 20% Nickel 25% Chromium Type 310 Stainless |

14 16 18 20 24 |

3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

9.5 7.9 6.4 4.8 3.2 |

18E4S20-G-E2-* 20E4S20-G-E2-* 24E4S20-G-E2-* |

18J4S20-G-J2-* 20J4S20-G-J2-* 24J4S20-G-J2-* |

14K4S20-G-K5-* 16K4S20-G-K2-* 18K4S20-G-K2-* 20K4S20-G-K2-* 24K4S20-G-K2-* |

18T4S20-G-T2-* 20T4S20-G-T2-* 24T4S20-G-T2-* |

| Thermocouple

Types E, J, K, T - Plug and Jack Jab Style plug is standard where "3" is indicated in the part number. Example: K3 = K1 + K5 (see Plug and Jack section for pictures and descriptions). Thermocouples normally have the Plug on the thermocouple and the Jack on the Extension Wire, however, they may be made either way. Grounded junctions (G) are standard. |

||||||||

| Application | Tube Materials |

Wire Gauge |

Outside Diameter |

Type E | Type J | Type K | Type T | |

| Inch | mm | |||||||

| Sulfurous Atmospheres |

#7 Alloy (446) 23% Chromium Iron Type 446 Stainless |

14 |

3/8 (.3750) |

9.5 |

14J4S7-G-J6-* | 14K4S7-G-K6-* | |

|

| Used in food, beverage, chemical and other applications |

#8 Alloy (304) 10 % Nickel 19% Chromium Type 304 Stainless |

8 11 14 16 18 20 24 |

3/4 (.7500) 1/2 (.5000) 3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

19.1 12.7 9.5 7.9 6.4 4.8 3.2 |

18E4S8-G-E3-* 20E4S8-G-E3-* 24E4S8-G-E3-* |

18J4S8-G-J3-* 20J4S8-G-J3-* 24J4S8-G-J3-* |

8K4S8-G-K9-* 11K4S8-G-K6-* 14K4S8-G-K6-* 16K4S8-G-K3-* 18K4S8-G-K3-* 20K4S8-G-K3-* 24K4S8-G-K3-* |

18T4S8-G-T3-* 20T4S8-G-T3-* 24T4S8-G-T3-* |

| Used in most applications, good corrosion resistance |

#9 Alloy (600) 77 % Nickel 15% Chromium Stainless |

8 11 14 16 18 20 24 |

3/4 (.7500) 1/2 (.5000) 3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

19.1 12.7 9.5 7.9 6.4 4.8 3.2 |

18E4S9-G-E3-* 20E4S9-G-E3-* 24E4S9-G-E3-* |

18J4S9-G-J3-* 20J4S9-G-J3-* 24J4S9-G-J3-* |

8K4S9-G-K9-* 11K4S9-G-K6-* 14K4S9-G-K6-* 16K4S9-G-K3-* 18K4S9-G-K3-* 20K4S9-G-K3-* 24K4S9-G-K3-* |

18T4S9-G-T3-* 20T4S9-G-T3-* 24T4S9-G-T3-* |

| Food and chemical applications |

#16 Alloy (316) 12% Nickel 17% Chromium Type 316 Stainless |

11 14 16 18 20 24 |

1/2 (.5000) 3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

12.7 9.5 7.9 6.4 4.8 3.2 |

18E4S16-G-E3-* 20E4S16-G-E3-* 24E4S16-G-E3-* |

11J4S16-G-J4-* 14J4S16-G-J4-* 16J4S16-G-J3-* 18J4S16-G-J3-* 20J4S16-G-J3-* 24J4S16-G-J3-* |

11K4S16-G-K6-* 14K4S16-G-K6-* 16K4S16-G-K3-* 18K4S16-G-K3-* 20K4S16-G-K3-* 24K4S16-G-K3-* |

18T4S16-G-T3-* 20T4S16-G-T3-* 24T4S16-G-T3-* |

| Mechanical and corrosion resistance,

often used in chemical industries |

#20 Alloy (310) 20% Nickel 25% Chromium Type 310 Stainless |

14 16 18 20 24 |

3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

9.5 7.9 6.4 4.8 3.2 |

18E4S20-G-E3-* 20E4S20-G-E3-* 24E4S20-G-E3-* |

18J4S20-G-J3-* 20J4S20-G-J3-* 24J4S20-G-J3-* |

14K4S20-G-K6-* 16K4S20-G-K3-* 18K4S20-G-K3-* 20K4S20-G-K3-* 24K4S20-G-K3-* |

18T4S20-G-T3-* 20T4S20-G-T3-* 24T4S20-G-T3-* |

| Thermocouple

Types E, J, K, T - Open Terminal (OT) Ceramic Head Used where wire connections will be in a clean environment and may be left exposed. Grounded junctions (G) are standard. |

||||||||

| Application | Tube Materials |

Wire Gauge |

Outside Diameter |

Type E | Type J | Type K | Type T | |

| Inch | mm | |||||||

| Sulfurous Atmospheres |

#7 Alloy (446) 23% Chromium Iron Type 446 Stainless |

14 |

3/8 (.3750) |

9.5 |

14J4S7-G-OT-* | 14K4S7-G-OT-* | |

|

| Used in food, beverage, chemical and other applications |

#8 Alloy (304) 10 % Nickel 19% Chromium Type 304 Stainless |

8 11 14 16 18 20 24 |

3/4 (.7500) 1/2 (.5000) 3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

19.1 12.7 9.5 7.9 6.4 4.8 3.2 |

18E4S8-G-OT-* 20E4S8-G-OT-* 24E4S8-G-OT-* |

18J4S8-G-OT-* 20J4S8-G-OT-* 24J4S8-G-OT-* |

8K4S8-G-OT-* 11K4S8-G-OT-* 14K4S8-G-OT-* 16K4S8-G-OT-* 18K4S8-G-OT-* 20K4S8-G-OT-* 24K4S8-G-OT-* |

18T4S8-G-OT-* 20T4S8-G-OT-* 24T4S8-G-OT-* |

| Used in most applications, good corrosion resistance |

#9 Alloy (600) 77 % Nickel 15% Chromium Stainless |

8 11 14 16 18 20 24 |

3/4 (.7500) 1/2 (.5000) 3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

19.1 12.7 9.5 7.9 6.4 4.8 3.2 |

18E4S9-G-OT-* 20E4S9-G-OT-* 24E4S9-G-OT-* |

18J4S9-G-OT-* 20J4S9-G-OT-* 24J4S9-G-OT-* |

8K4S9-G-OT-* 11K4S9-G-OT-* 14K4S9-G-OT-* 16K4S9-G-OT-* 18K4S9-G-OT-* 20K4S9-G-OT-* 24K4S9-G-OT-* |

18T4S9-G-OT-* 20T4S9-G-OT-* 24T4S9-G-OT-* |

| Food and chemical applications |

#16 Alloy (316) 12% Nickel 17% Chromium Type 316 Stainless |

11 14 16 18 20 24 |

1/2 (.5000) 3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

12.7 9.5 7.9 6.4 4.8 3.2 |

18E4S16-G-OT-* 20E4S16-G-OT-* 24E4S16-G-OT-* |

11J4S16-G-OT-* 14J4S16-G-OT-* 16J4S16-G-OT-* 18J4S16-G-OT-* 20J4S16-G-OT-* 24J4S16-G-OT-* |

11K4S16-G-OT-* 14K4S16-G-OT-* 16K4S16-G-OT-* 18K4S16-G-OT-* 20K4S16-G-OT-* 24K4S16-G-OT-* |

18T4S16-G-OT-* 20T4S16-G-OT-* 24T4S16-G-OT-* |

| Mechanical and corrosion resistance,

often used in chemical industries |

#20 Alloy (310) 20% Nickel 25% Chromium Type 310 Stainless |

14 16 18 20 24 |

3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

9.5 7.9 6.4 4.8 3.2 |

18E4S20-G-OT-* 20E4S20-G-OT-* 24E4S20-G-OT-* |

18J4S20-G-OT-* 20J4S20-G-OT-* 24J4S20-G-OT-* |

14K4S20-G-OT-* 16K4S20-G-OT-* 18K4S20-G-OT-* 20K4S20-G-OT-* 24K4S20-G-OT-* |

18T4S20-G-OT-* 20T4S20-G-OT-* 24T4S20-G-OT-* |

| Types

E, J, K, T - Hexagonal Fitting (HX) Used where a 1/2" x 1/2" NPT hexagonal fitting is desirable for mounting to furnace and head (or other fitting). Other size hexagonal fittings are also available. Grounded junctions (G) are standard. |

||||||||

| Application | Tube Materials |

Wire Gauge |

Outside Diameter |

Type E | Type J | Type K | Type T | |

| Inch | mm | |||||||

| Sulfurous Atmospheres |

#7 Alloy (446) 23% Chromium Iron Type 446 Stainless |

14 |

3/8 (.3750) |

9.5 |

14J4S7-G-HX-* | 14K4S7-G-HX-* | |

|

| Used in food, beverage, chemical and other applications |

#8 Alloy (304) 10 % Nickel 19% Chromium Type 304 Stainless |

8 11 14 16 18 20 24 |

3/4 (.7500) 1/2 (.5000) 3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

19.1 12.7 9.5 7.9 6.4 4.8 3.2 |

18E4S8-G-HX-* 20E4S8-G-HX-* 24E4S8-G-HX-* |

18J4S8-G-HX-* 20J4S8-G-HX-* 24J4S8-G-HX-* |

8K4S8-G-HX-* 11K4S8-G-HX-* 14K4S8-G-HX-* 16K4S8-G-HX-* 18K4S8-G-HX-* 20K4S8-G-HX-* 24K4S8-G-HX-* |

18T4S8-G-HX-* 20T4S8-G-HX-* 24T4S8-G-HX-* |

| Used in most applications, good corrosion resistance |

#9 Alloy (600) 77 % Nickel 15% Chromium Stainless |

8 11 14 16 18 20 24 |

3/4 (.7500) 1/2 (.5000) 3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

19.1 12.7 9.5 7.9 6.4 4.8 3.2 |

18E4S9-G-HX-* 20E4S9-G-HX-* 24E4S9-G-HX-* |

18J4S9-G-HX-* 20J4S9-G-HX-* 24J4S9-G-HX-* |

8K4S9-G-HX-* 11K4S9-G-HX-* 14K4S9-G-HX-* 16K4S9-G-HX-* 18K4S9-G-HX-* 20K4S9-G-HX-* 24K4S9-G-HX-* |

18T4S9-G-HX-* 20T4S9-G-HX-* 24T4S9-G-HX-* |

| Food and chemical applications |

#16 Alloy (316) 12% Nickel 17% Chromium Type 316 Stainless |

11 14 16 18 20 24 |

1/2 (.5000) 3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

12.7 9.5 7.9 6.4 4.8 3.2 |

18E4S16-G-HX-* 20E4S16-G-HX-* 24E4S16-G-HX-* |

11J4S16-G-HX-* 14J4S16-G-HX-* 16J4S16-G-HX-* 18J4S16-G-HX-* 20J4S16-G-HX-* 24J4S16-G-HX-* |

11K4S16-G-HX-* 14K4S16-G-HX-* 16K4S16-G-HX-* 18K4S16-G-HX-* 20K4S16-G-HX-* 24K4S16-G-HX-* |

18T4S16-G-HX-* 20T4S16-G-HX-* 24T4S16-G-HX-* |

| Mechanical and corrosion resistance,

often used in chemical industries |

#20 Alloy (310) 20% Nickel 25% Chromium Type 310 Stainless |

14 16 18 20 24 |

3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

9.5 7.9 6.4 4.8 3.2 |

18E4S20-G-HX-* 20E4S20-G-HX-* 24E4S20-G-HX-* |

18J4S20-G-HX-* 20J4S20-G-HX-* 24J4S20-G-HX-* |

14K4S20-G-HX-* 16K4S20-G-HX-* 18K4S20-G-HX-* 20K4S20-G-HX-* 24K4S20-G-HX-* |

18T4S20-G-HX-* 20T4S20-G-HX-* 24T4S20-G-HX-* |

| Thermocouple

Types E, J, K, T - Hexagonal Fitting (HX) and Weatherproof Head (WH) A 1/2" x 1/2" NPT thread is standard (others available upon request). This provides a 1/2" NPT thread to furnace and a 1/2" NPT thread for the head. Grounded junctions (G) are standard. |

||||||||

| Application | Tube Materials |

Wire Gauge |

Outside Diameter |

Type E | Type J | Type K | Type T | |

| Inch | mm | |||||||

| Sulfurous Atmospheres |

#7 Alloy (446) 23% Chromium Iron Type 446 Stainless |

14 |

3/8 (.3750) |

9.5 |

14J4S7-G-HX-WH-* | 14K4S7-G-HX-WH-* | |

|

| Used in food, beverage, chemical and other applications |

#8 Alloy (304) 10 % Nickel 19% Chromium Type 304 Stainless |

8 11 14 16 18 20 24 |

3/4 (.7500) 1/2 (.5000) 3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

19.1 12.7 9.5 7.9 6.4 4.8 3.2 |

18E4S8-G-HX-WH-* 20E4S8-G-HX-WH-* 24E4S8-G-HX-WH-* |

18J4S8-G-HX-WH-* 20J4S8-G-HX-WH-* 24J4S8-G-HX-WH-* |

8K4S8-G-HX-WH-* 11K4S8-G-HX-WH-* 14K4S8-G-HX-WH-* 16K4S8-G-HX-WH-* 18K4S8-G-HX-WH-* 20K4S8-G-HX-WH-* 24K4S8-G-HX-WH-* |

18T4S8-G-HX-WH-* 20T4S8-G-HX-WH-* 24T4S8-G-HX-WH-* |

| Used in most applications, good corrosion resistance |

#9 Alloy (600) 77 % Nickel 15% Chromium Stainless |

8 11 14 16 18 20 24 |

3/4 (.7500) 1/2 (.5000) 3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

19.1 12.7 9.5 7.9 6.4 4.8 3.2 |

18E4S9-G-HX-WH-* 20E4S9-G-HX-WH-* 24E4S9-G-HX-WH-* |

18J4S9-G-HX-WH-* 20J4S9-G-HX-WH-* 24J4S9-G-HX-WH-* |

8K4S9-G-HX-WH-* 11K4S9-G-HX-WH-* 14K4S9-G-HX-WH-* 16K4S9-G-HX-WH-* 18K4S9-G-HX-WH-* 20K4S9-G-HX-WH-* 24K4S9-G-HX-WH-* |

18T4S9-G-HX-WH-* 20T4S9-G-HX-WH-* 24T4S9-G-HX-WH-* |

| Food and chemical applications |

#16 Alloy (316) 12% Nickel 17% Chromium Type 316 Stainless |

11 14 16 18 20 24 |

1/2 (.5000) 3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

12.7 9.5 7.9 6.4 4.8 3.2 |

18E4S16-G-HX-WH-* 20E4S16-G-HX-WH-* 24E4S16-G-HX-WH-* |

11J4S16-G-HX-WH-* 14J4S16-G-HX-WH-* 16J4S16-G-HX-WH-* 18J4S16-G-HX-WH-* 20J4S16-G-HX-WH-* 24J4S16-G-HX-WH-* |

11K4S16-G-HX-WH-* 14K4S16-G-HX-WH-* 16K4S16-G-HX-WH-* 18K4S16-G-HX-WH-* 20K4S16-G-HX-WH-* 24K4S16-G-HX-WH-* |

18T4S16-G-HX-WH-* 20T4S16-G-HX-WH-* 24T4S16-G-HX-WH-* |

| Mechanical and corrosion resistance,

often used in chemical industries |

#20 Alloy (310) 20% Nickel 25% Chromium Type 310 Stainless |

14 16 18 20 24 |

3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

9.5 7.9 6.4 4.8 3.2 |

18E4S20-G-HX-WH-* 20E4S20-G-HX-WH-* 24E4S20-G-HX-WH-* |

18J4S20-G-HX-WH-* 20J4S20-G-HX-WH-* 24J4S20-G-HX-WH-* |

14K4S20-G-HX-WH-* 16K4S20-G-HX-WH-* 18K4S20-G-HX-WH-* 20K4S20-G-HX-WH-* 24K4S20-G-HX-WH-* |

18T4S20-G-HX-WH-* 20T4S20-G-HX-WH-* 24T4S20-G-HX-WH-* |

| Types

E, J, K, T - Weatherproof Head (WH) and Compression Fitting (CF) Many other style of heads are also available. Grounded junctions (G) are standard. |

||||||||

| Application | Tube Materials |

Wire Gauge |

Outside Diameter |

Type E | Type J | Type K | Type T | |

| Inch | mm | |||||||

| Sulfurous Atmospheres |

#7 Alloy (446) 23% Chromium Iron Type 446 Stainless |

14 |

3/8 (.3750) |

9.5 |

14J4S7-G-WH-*-CF | 14K4S7-G-WH-*-CF | |

|

| Used in food, beverage, chemical and other applications |

#8 Alloy (304) 10 % Nickel 19% Chromium Type 304 Stainless |

8 11 14 16 18 20 24 |

3/4 (.7500) 1/2 (.5000) 3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

19.1 12.7 9.5 7.9 6.4 4.8 3.2 |

18E4S8-G-WH-*-CF 20E4S8-G-WH-*-CF 24E4S8-G-WH-*-CF |

18J4S8-G-WH-*-CF 20J4S8-G-WH-*-CF 24J4S8-G-WH-*-CF |

8K4S8-G-WH-*-CF 11K4S8-G-WH-*-CF 14K4S8-G-WH-*-CF 16K4S8-G-WH-*-CF 18K4S8-G-WH-*-CF 20K4S8-G-WH-*-CF 24K4S8-G-WH-*-CF |

18T4S8-G-WH-*-CF 20T4S8-G-WH-*-CF 24T4S8-G-WH-*-CF |

| Used in most applications, good corrosion resistance |

#9 Alloy (600) 77 % Nickel 15% Chromium Stainless |

8 11 14 16 18 20 24 |

3/4 (.7500) 1/2 (.5000) 3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

19.1 12.7 9.5 7.9 6.4 4.8 3.2 |

18E4S9-G-WH-*-CF 20E4S9-G-WH-*-CF 24E4S9-G-WH-*-CF |

18J4S9-G-WH-*-CF 20J4S9-G-WH-*-CF 24J4S9-G-WH-*-CF |

8K4S9-G-WH-*-CF 11K4S9-G-WH-*-CF 14K4S9-G-WH-*-CF 16K4S9-G-WH-*-CF 18K4S9-G-WH-*-CF 20K4S9-G-WH-*-CF 24K4S9-G-WH-*-CF |

18T4S9-G-WH-*-CF 20T4S9-G-WH-*-CF 24T4S9-G-WH-*-CF |

| Food and chemical applications |

#16 Alloy (316) 12% Nickel 17% Chromium Type 316 Stainless |

11 14 16 18 20 24 |

1/2 (.5000) 3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

12.7 9.5 7.9 6.4 4.8 3.2 |

18E4S16-G-WH-*-CF 20E4S16-G-WH-*-CF 24E4S16-G-WH-*-CF |

11J4S16-G-WH-*-CF 14J4S16-G-WH-*-CF 16J4S16-G-WH-*-CF 18J4S16-G-WH-*-CF 20J4S16-G-WH-*-CF 24J4S16-G-WH-*-CF |

11K4S16-G-WH-*-CF 14K4S16-G-WH-*-CF 16K4S16-G-WH-*-CF 18K4S16-G-WH-*-CF 20K4S16-G-WH-*-CF 24K4S16-G-WH-*-CF |

18T4S16-G-WH-*-CF 20T4S16-G-WH-*-CF 24T4S16-G-WH-*-CF |

| Mechanical and corrosion resistance,

often used in chemical industries |

#20 Alloy (310) 20% Nickel 25% Chromium Type 310 Stainless |

14 16 18 20 24 |

3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

9.5 7.9 6.4 4.8 3.2 |

18E4S20-G-WH-*-CF 20E4S20-G-WH-*-CF 24E4S20-G-WH-*-CF |

18J4S20-G-WH-*-CF 20J4S20-G-WH-*-CF 24J4S20-G-WH-*-CF |

14K4S20-G-WH-*-CF 16K4S20-G-WH-*-CF 18K4S20-G-WH-*-CF 20K4S20-G-WH-*-CF 24K4S20-G-WH-*-CF |

18T4S20-G-WH-*-CF 20T4S20-G-WH-*-CF 24T4S20-G-WH-*-CF |

| Thermocouple

Types E, J, K, T - Transition Fitting (TR) Provides a Transition Fitting to protect the joining of the extension wire to the swaged thermocouple. Usually smaller gauge thermocouple wires are joined to larger gauge extension wires. Connection is not as mechanically strong as use of plugs and jacks or weatherproof heads. For other diameters consult factory. Grounded junctions (G) are standard, coiled relief spring is optional. Insert length of metal sheath (Y) and total length (X). 3 inch leads are standard. |

||||||||

| Application | Tube Materials |

Wire Gauge |

Outside Diameter |

Type E | Type J | Type K | Type T | |

| Inch | mm | |||||||

| Sulfurous Atmospheres |

#7 Alloy (446) 23% Chromium Iron Type 446 Stainless |

14 |

3/8 (.3750) |

9.5 |

14J4S7-G-Y-TR-X | 14K4S7-G-Y-TR-X | |

|

| Used in food, beverage, chemical and other applications |

#8 Alloy (304) 10 % Nickel 19% Chromium Type 304 Stainless |

8 11 14 16 18 20 24 |

3/4 (.7500) 1/2 (.5000) 3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

19.1 12.7 9.5 7.9 6.4 4.8 3.2 |

18E4S8-G-Y-TR-X 20E4S8-G-Y-TR-X 24E4S8-G-Y-TR-X |

18J4S8-G-Y-TR-X 20J4S8-G-Y-TR-X 24J4S8-G-Y-TR-X |

8K4S8-G-Y-TR-X 11K4S8-G-Y-TR-X 14K4S8-G-Y-TR-X 16K4S8-G-Y-TR-X 18K4S8-G-Y-TR-X 20K4S8-G-Y-TR-X 24K4S8-G-Y-TR-X |

18T4S8-G-Y-TR-X 20T4S8-G-Y-TR-X 24T4S8-G-Y-TR-X |

| Used in most applications, good corrosion resistance |

#9 Alloy (600) 77 % Nickel 15% Chromium Stainless |

8 11 14 16 18 20 24 |

3/4 (.7500) 1/2 (.5000) 3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

19.1 12.7 9.5 7.9 6.4 4.8 3.2 |

18E4S9-G-Y-TR-X 20E4S9-G-Y-TR-X 24E4S9-G-Y-TR-X |

18J4S9-G-Y-TR-X 20J4S9-G-Y-TR-X 24J4S9-G-Y-TR-X |

8K4S9-G-Y-TR-X 11K4S9-G-Y-TR-X 14K4S9-G-Y-TR-X 16K4S9-G-Y-TR-X 18K4S9-G-Y-TR-X 20K4S9-G-Y-TR-X 24K4S9-G-Y-TR-X |

18T4S9-G-Y-TR-X 20T4S9-G-Y-TR-X 24T4S9-G-Y-TR-X |

| Food and chemical applications |

#16 Alloy (316) 12% Nickel 17% Chromium Type 316 Stainless |

11 14 16 18 20 24 |

1/2 (.5000) 3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

12.7 9.5 7.9 6.4 4.8 3.2 |

18E4S16-G-Y-TR-X 20E4S16-G-Y-TR-X 24E4S16-G-Y-TR-X |

11J4S16-G-Y-TR-X 14J4S16-G-Y-TR-X 16J4S16-G-Y-TR-X 18J4S16-G-Y-TR-X 20J4S16-G-Y-TR-X 24J4S16-G-Y-TR-X |

11K4S16-G-Y-TR-X 14K4S16-G-Y-TR-X 16K4S16-G-Y-TR-X 18K4S16-G-Y-TR-X 20K4S16-G-Y-TR-X 24K4S16-G-Y-TR-X |

18T4S16-G-Y-TR-X 20T4S16-G-Y-TR-X 24T4S16-G-Y-TR-X |

| Mechanical and corrosion resistance,

often used in chemical industries |

#20 Alloy (310) 20% Nickel 25% Chromium Type 310 Stainless |

14 16 18 20 24 |

3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

9.5 7.9 6.4 4.8 3.2 |

18E4S20-G-Y-TR-X 20E4S20-G-Y-TR-X 24E4S20-G-Y-TR-X |

18J4S20-G-Y-TR-X 20J4S20-G-Y-TR-X 24J4S20-G-Y-TR-X |

14K4S20-G-Y-TR-X 16K4S20-G-Y-TR-X 18K4S20-G-Y-TR-X 20K4S20-G-Y-TR-X 24K4S20-G-Y-TR-X |

18T4S20-G-Y-TR-X 20T4S20-G-Y-TR-X 24T4S20-G-Y-TR-X |

| Thermocouple

Types E, J, K, T - Transition Fitting (TR) and Flexible Extension (FE) Provides a Transition Fitting to protect the joining of the extension wire to the swaged thermocouple. Usually smaller gauge thermocouple wires are joined to larger gauge extension wires. Connection is not as mechanically strong as use of plugs and jacks or weatherproof heads. For other diameters consult factory. Grounded junctions (G) are standard, coiled relief spring is optional. Insert length of metal sheath (Y), Total length (X), and Flexible Extension length (Z). 3 inch leads are standard. |

||||||||

| Application | Tube Materials |

Wire Gauge |

Outside Diameter |

Type E | Type J | Type K | Type T | |

| Inch | mm | |||||||

| Sulfurous Atmospheres |

#7 Alloy (446) 23% Chromium Iron Type 446 Stainless |

14 |

3/8 (.3750) |

9.5 |

14J4S7-G-Y-FE-Z-X | 14K4S7-G-Y-FE-Z-X | |

|

| Used in food, beverage, chemical and other applications |

#8 Alloy (304) 10 % Nickel 19% Chromium Type 304 Stainless |

8 11 14 16 18 20 24 |

3/4 (.7500) 1/2 (.5000) 3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

19.1 12.7 9.5 7.9 6.4 4.8 3.2 |

18E4S8-G-Y-FE-Z-X 20E4S8-G-Y-FE-Z-X 24E4S8-G-Y-FE-Z-X |

18J4S8-G-Y-FE-Z-X 20J4S8-G-Y-FE-Z-X 24J4S8-G-Y-FE-Z-X |

8K4S8-G-Y-FE-Z-X 11K4S8-G-Y-FE-Z-X 14K4S8-G-Y-FE-Z-X 16K4S8-G-Y-FE-Z-X 18K4S8-G-Y-FE-Z-X 20K4S8-G-Y-FE-Z-X 24K4S8-G-Y-FE-Z-X |

18T4S8-G-Y-FE-Z-X 20T4S8-G-Y-FE-Z-X 24T4S8-G-Y-FE-Z-X |

| Used in most applications, good corrosion resistance |

#9 Alloy (600) 77 % Nickel 15% Chromium Stainless |

8 11 14 16 18 20 24 |

3/4 (.7500) 1/2 (.5000) 3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

19.1 12.7 9.5 7.9 6.4 4.8 3.2 |

18E4S9-G-Y-FE-Z-X 20E4S9-G-Y-FE-Z-X 24E4S9-G-Y-FE-Z-X |

18J4S9-G-Y-FE-Z-X 20J4S9-G-Y-FE-Z-X 24J4S9-G-Y-FE-Z-X |

8K4S9-G-Y-FE-Z-X 11K4S9-G-Y-FE-Z-X 14K4S9-G-Y-FE-Z-X 16K4S9-G-Y-FE-Z-X 18K4S9-G-Y-FE-Z-X 20K4S9-G-Y-FE-Z-X 24K4S9-G-Y-FE-Z-X |

18T4S9-G-Y-FE-Z-X 20T4S9-G-Y-FE-Z-X 24T4S9-G-Y-FE-Z-X |

| Food and chemical applications |

#16 Alloy (316) 12% Nickel 17% Chromium Type 316 Stainless |

11 14 16 18 20 24 |

1/2 (.5000) 3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

12.7 9.5 7.9 6.4 4.8 3.2 |

18E4S16-G-Y-FE-Z-X 20E4S16-G-Y-FE-Z-X 24E4S16-G-Y-FE-Z-X |

11J4S16-G-Y-FE-Z-X 14J4S16-G-Y-FE-Z-X 16J4S16-G-Y-FE-Z-X 18J4S16-G-Y-FE-Z-X 20J4S16-G-Y-FE-Z-X 24J4S16-G-Y-FE-Z-X |

11K4S16-G-Y-FE-Z-X 14K4S16-G-Y-FE-Z-X 16K4S16-G-Y-FE-Z-X 18K4S16-G-Y-FE-Z-X 20K4S16-G-Y-FE-Z-X 24K4S16-G-Y-FE-Z-X |

18T4S16-G-Y-FE-Z-X 20T4S16-G-Y-FE-Z-X 24T4S16-G-Y-FE-Z-X |

| Mechanical and corrosion resistance,

often used in chemical industries |

#20 Alloy (310) 20% Nickel 25% Chromium Type 310 Stainless |

14 16 18 20 24 |

3/8 (.3750) 5/16 (.3125) 1/4 (.2500) 3/16 (.1875) 1/8 (.1250) |

9.5 7.9 6.4 4.8 3.2 |

18E4S20-G-Y-FE-Z-X 20E4S20-G-Y-FE-Z-X 24E4S20-G-Y-FE-Z-X |

18J4S20-G-Y-FE-Z-X 20J4S20-G-Y-FE-Z-X 24J4S20-G-Y-FE-Z-X |

14K4S20-G-Y-FE-Z-X 16K4S20-G-Y-FE-Z-X 18K4S20-G-Y-FE-Z-X 20K4S20-G-Y-FE-Z-X 24K4S20-G-Y-FE-Z-X |

18T4S20-G-Y-FE-Z-X 20T4S20-G-Y-FE-Z-X 24T4S20-G-Y-FE-Z-X |

| © Copyright 2005 Arklay S. Richards Co., Inc. |